Gearbox

The goal of this project was to design and analyze a gearbox with a gear ratio of 240:1. The gearbox was limited by a series of constraints including strength and life; it needed to have minimum life of 25,000 hours, to be able to support a 50 lbf overhanging load at the output shaft, and achieve a maximum rotational speed of 240 RPM at the input shaft. Manufacturability was also a concern as the designs would have to be implemented using only prototype methods such as milling, turning, tapping, and on purchasable stock.

Methods + Machines Used:

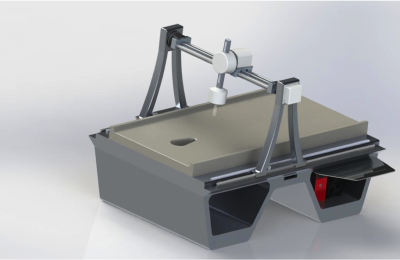

CAD – SolidWorks was used to design, render and animate the gearbox

FEA – to check the effects of the 50 lbf loading on the output shaft

Component Life Analysis – to ensure the bearings met the minimum 25,000 hours

Tolerance Analysis – to ensure all our components fit together and were manufacturable